Harnessing the Power of Electrical Data Loggers: Usage and Advantages

In the rapidly evolving realm of electrical engineering, precision, efficiency, and safety are paramount. Enter the unsung hero of this domain: the electrical data logger. A device designed to monitor, record, and analyze electrical parameters over time, the electrical data logger has become an indispensable tool for maintaining optimal performance and mitigating risks. In this blog, we’ll delve into the usage of electrical data loggers and explore the advantages they offer to professionals in the electrical field.

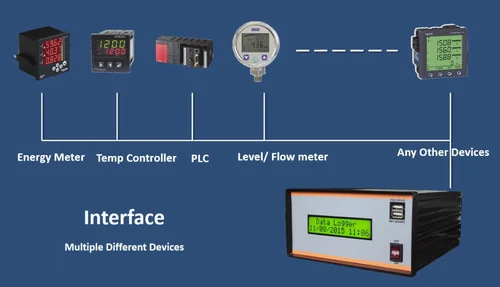

Understanding Electrical Data Loggers

An electrical data logger is a sophisticated instrument that captures crucial electrical data, transforming it into actionable insights. It’s like a watchful guardian that monitors electrical systems, records various parameters, and helps detect anomalies before they escalate into major issues.

How to Use Electrical Data Loggers

How to Use Electrical Data Loggers

Select the Right Logger: Choose a data logger based on your specific needs. Consider factors such as the type of parameters you need to monitor (voltage, current, temperature, etc.), the expected duration of monitoring, and the environmental conditions.

Installation: Properly install the data logger as per the manufacturer’s guidelines. Ensure that sensors are correctly connected to the electrical system or equipment you intend to monitor.

Configuration: Set up the data logger by configuring the parameters you want to monitor, the sampling rate (how frequently data is recorded), and any alert thresholds.

Data Collection: Let the data logger do its job. It will continuously gather data according to your settings.

Data Retrieval: Depending on the logger’s capabilities, you can retrieve data via USB, Bluetooth, Wi-Fi, or cellular connectivity. Some advanced models offer real-time data access through cloud-based platforms.

Analysis: Use specialized software provided by the manufacturer to analyze the collected data. You can visualize trends, identify irregularities, and make informed decisions based on the insights.

Advantages of Using Electrical Data Loggers

Production analysis involves closely examining the manufacturing process to identify areas for improvement, enhance quality control, and optimize resource utilization. Here’s why it’s a game-changer:

Early Problem Detection: By continuously monitoring electrical parameters, data loggers can detect anomalies, such as voltage fluctuations and current surges, allowing for timely intervention before issues worsen.

Preventive Maintenance: Armed with historical data, you can schedule maintenance activities proactively, reducing downtime and preventing costly breakdowns.

Energy Efficiency: Data loggers help track energy consumption patterns, enabling you to identify energy-saving opportunities and optimize usage.

Accurate Power Quality Analysis: Uncover power quality issues like voltage sags, surges, harmonics, and frequency variations, aiding in maintaining stable power distribution systems.

Remote Monitoring: Some data loggers offer remote monitoring, allowing engineers to keep an eye on systems from a distance and receive real-time alerts, enhancing responsiveness.

Compliance and Reporting: Maintain compliance with industry standards by generating detailed reports based on recorded data.

Enhanced Safety: Detect overheating issues and potential fire hazards by monitoring temperature variations in electrical components.

Efficient Load Management: Create load profiles by analyzing data, facilitating efficient distribution and load balancing.

Conclusion:

The integration of electrical data loggers has transformed the electrical engineering landscape, empowering professionals to operate with unprecedented accuracy and foresight. By harnessing the insights generated by these unassuming devices, organizations can optimize performance, ensure safety, and streamline operations. As technology continues to advance, the role of electrical data loggers will only become more vital, driving innovation and excellence in the field.

To get a free demonstration at your premise

Call us on 8291366254

Mail us at:prashant.yadav@oneunit.in